Metal stamping die technology has significantly transformed the landscape of precision manufacturing, particularly exemplified at Rui Rui Electric. This article delves into the critical role of metal stamping dies, their applications, and how Rui Rui Electric leverages this technology to achieve manufacturing excellence.

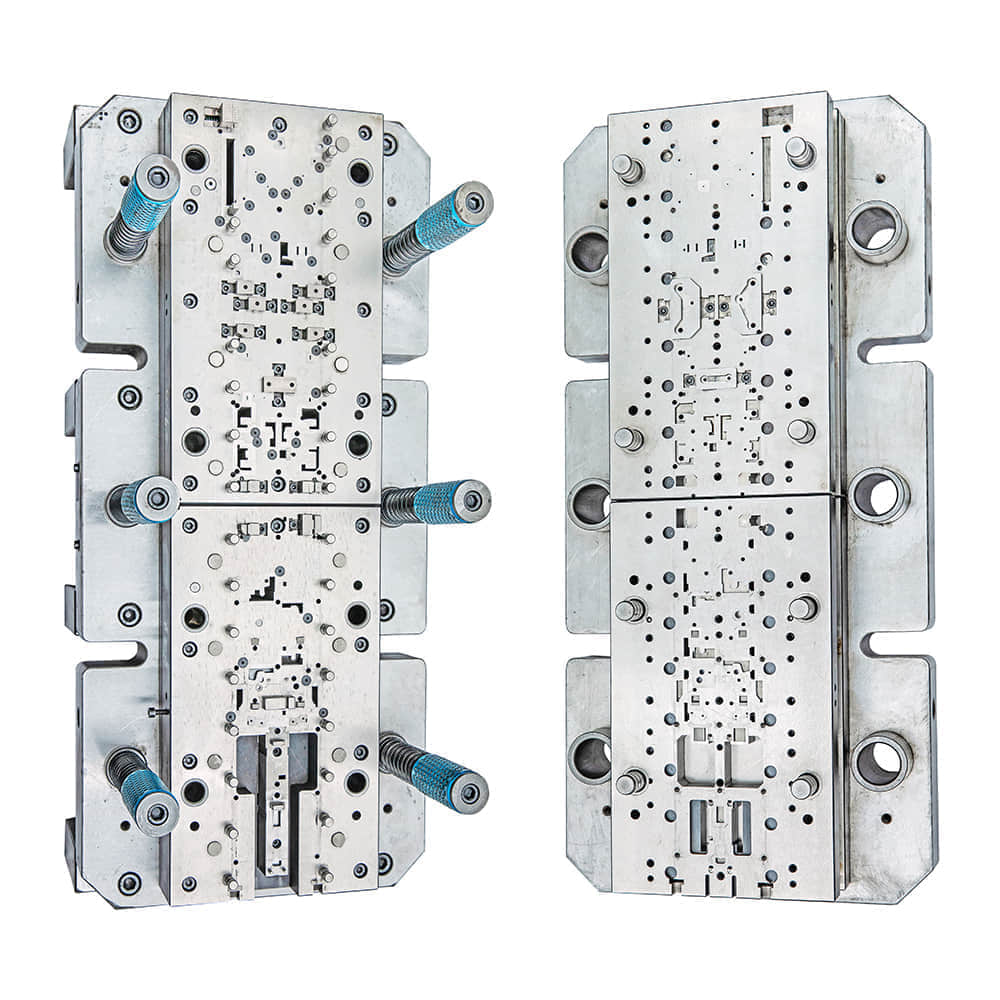

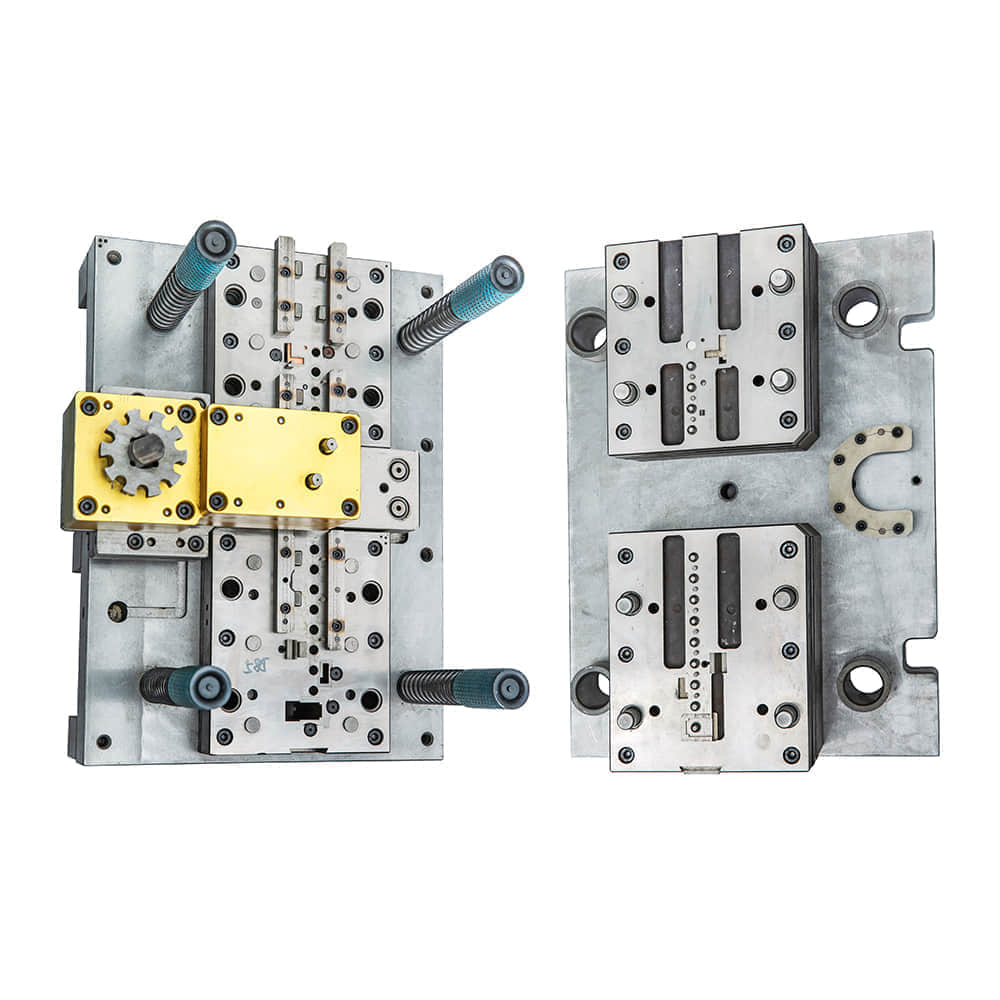

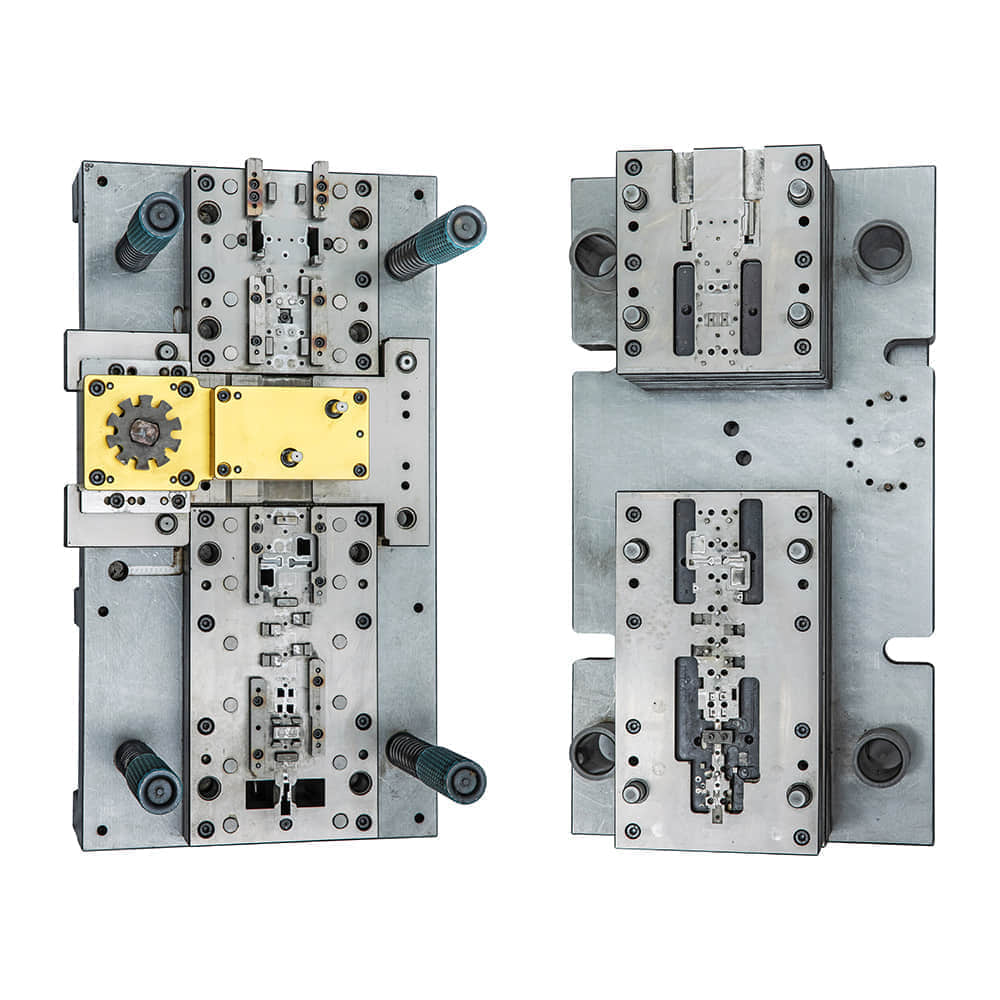

Metal stamping dies are crucial tools used in the fabrication of metal parts through processes like cutting, bending, and shaping. They are meticulously designed to withstand high pressures exerted by stamping presses, ensuring accurate replication of intricate designs and precise dimensional tolerances. At Rui Rui Electric, these dies form the backbone of their production capabilities, enabling the creation of high-quality components integral to various industries.

Rui Rui Electric, a leader in electrical component manufacturing, exemplifies the cutting-edge application of metal stamping dies. Specializing in components for renewable energy solutions, their use of advanced die technology allows for the efficient production of components crucial to solar panel assemblies and wind turbine systems. These components demand high precision and durability, qualities that metal stamping dies deliver with unmatched reliability. The design and construction of metal stamping dies are highly specialized processes at Rui Rui Electric. Engineers meticulously plan each die set to optimize efficiency and minimize material waste, crucial in high-volume production scenarios. Computer-aided design (CAD) software plays a pivotal role, enabling virtual simulations to refine die designs before physical construction begins. This iterative process ensures that the final dies meet exacting specifications, resulting in cost-effective manufacturing solutions without compromising quality.

Leave a Reply