In the vast landscape of manufacturing, the injection molded parts manufacturer stands as a crucial player, specializing in the creation of precision plastic parts. These manufacturers are not just simple factories; they are high-tech hubs where the art of plastics transformation meets the precision of engineering.

The Magic of Injection Molding

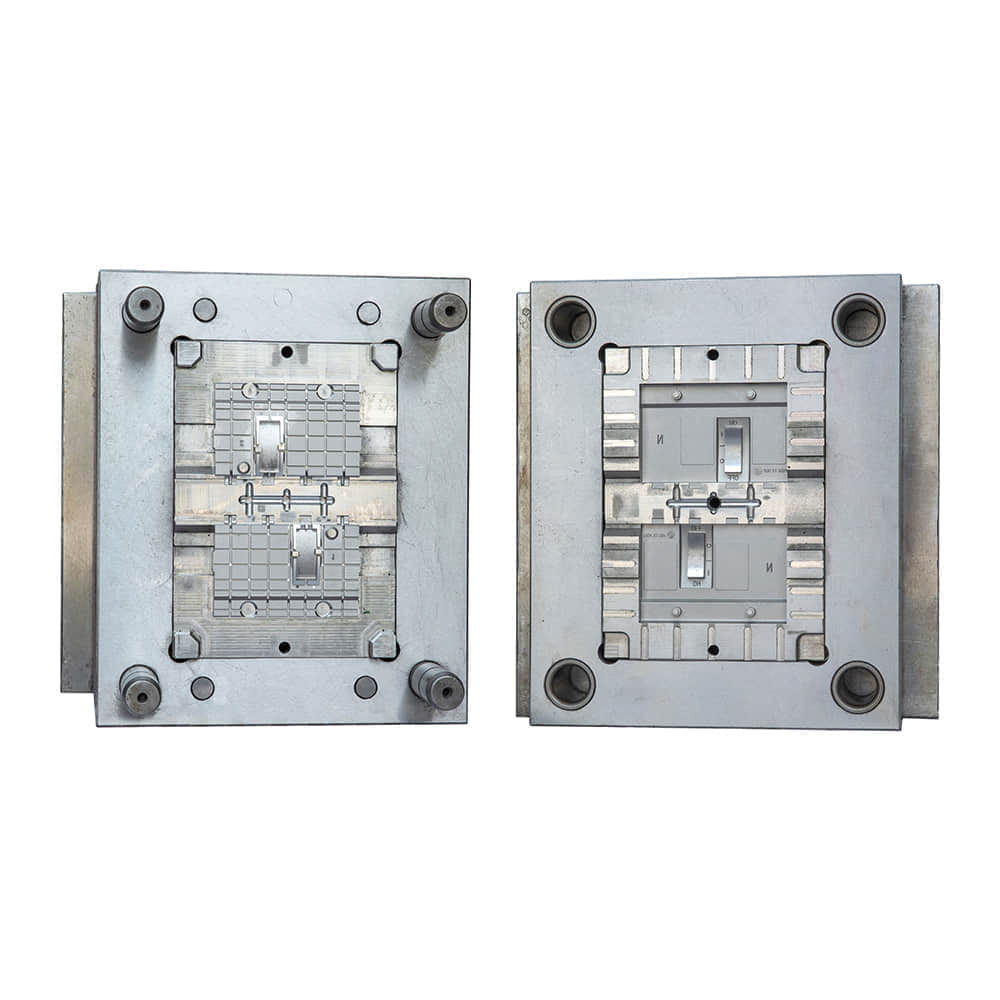

Injection molding is a complex process that involves injecting molten plastic into a mold cavity, which then cools and solidifies to form the desired part. It’s a process that requires meticulous attention to detail, as even the smallest variations can affect the final product’s quality. Injection molded parts manufacturers must have a deep understanding of materials, mold design, machine operations, and quality control. The Diverse Applications of Injection Molded Parts The versatility of injection molding is what makes it so popular across industries. From automotive components to medical devices, from consumer electronics to packaging containers, injection molded parts are everywhere. Manufacturers must be able to adapt their processes to meet the unique requirements of each industry, ensuring that the parts they produce are fit for purpose.

Leave a Reply