In today’s industrial landscape, the demand for safety and efficiency in fluid control systems has never been more critical. Among the various components used in these systems, the explosion-proof electric butterfly valve stands out as an essential device, especially in hazardous environments. This article delves into the significance of explosion-proof electric butterfly valves, their applications, and the role of OEM manufacturers in delivering high-quality solutions to meet industry needs.

Understanding Explosion-proof Electric Butterfly Valves

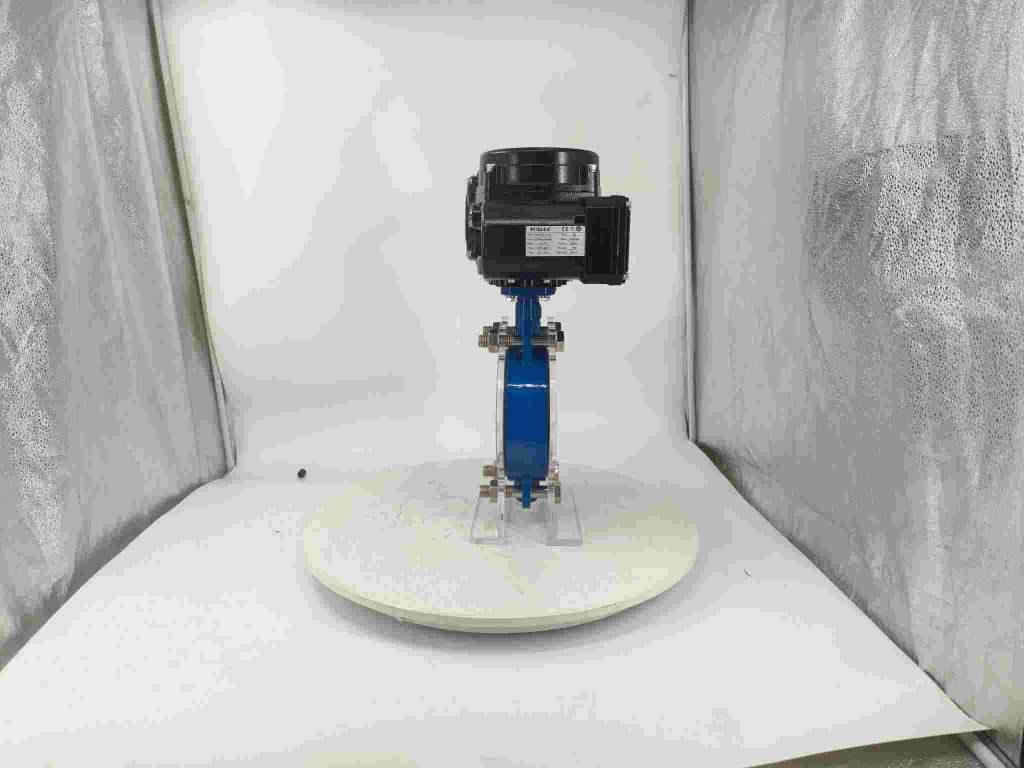

An explosion-proof electric butterfly valve is designed to control the flow of fluids—liquids or gases—while ensuring safety in environments that are prone to explosive atmospheres. These valves utilize a disc that rotates around a central axis to regulate flow. When the valve is fully open, the disc is parallel to the flow, while in a closed position, it is perpendicular, effectively blocking the passage. The term “explosion-proof” indicates that the valve is engineered to withstand and contain explosions caused by flammable gases or vapors. This is achieved through rigorous design standards, which often include reinforced materials, sealing technologies, and careful attention to the valve’s electrical components.

Leave a Reply